- Home

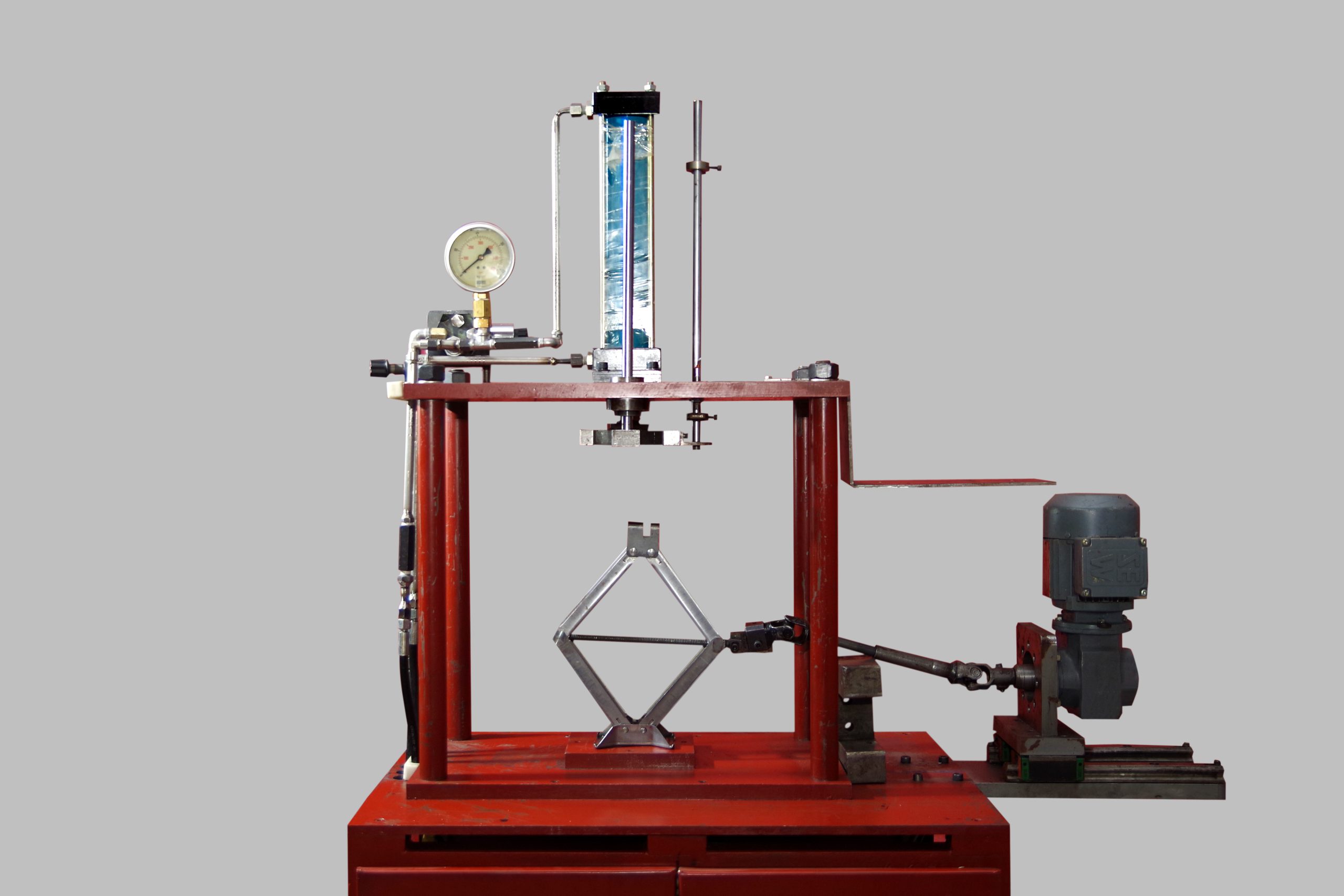

- Car Jacks Manufacturing

Car Jacks Manufacturing

Manufacturing car jacks involves several key features to ensure safety, reliability, and ease of use

Material Selection: Car jacks are typically made from durable materials such as steel or aluminum. The choice of material depends on factors such as load capacity, weight, and corrosion resistance.

Design Varieties: Car jacks come in various designs, including hydraulic jacks, scissor jacks, bottle jacks, and floor jacks. Manufacturers may offer different types to accommodate different vehicle weights, clearance heights, and usage scenarios.

Load Capacity: Car jacks are designed to lift vehicles of varying weights. Manufacturers specify the load capacity of their jacks to ensure safe lifting operations. Higher load capacities are typically required for larger vehicles like trucks and SUVs.

Mechanism and Operation: Car jacks utilize different lifting mechanisms, such as hydraulic, mechanical, or pneumatic systems. The design and operation of these mechanisms should be user-friendly, efficient, and capable of lifting vehicles with minimal effort.

Safety Features: Safety is paramount in car jack design. Manufacturers incorporate features such as safety locks, overload protection, and bypass valves to prevent accidents and ensure stable lifting operations. Clear instructions and warning labels are also provided to guide users on safe usage.

Durability and Stability: Car jacks need to withstand repeated use and heavy loads without failure. Sturdy construction, reinforced components, and stable bases are essential for ensuring durability and stability during lifting operations.

Portability and Storage: Car jacks should be lightweight and compact for easy transport and storage in vehicles. Some jacks feature collapsible or foldable designs to minimize space requirements when not in use.

Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process. This includes material inspections, dimensional checks, load testing, and functional testing to ensure that jacks meet industry standards and performance requirements.

Compliance with Standards: Car jacks must comply with relevant safety standards and regulations, such as ANSI/ASME standards in the United States or CE marking in the European Union. Manufacturers conduct testing and certification to demonstrate compliance with these standards.

Packaging and Documentation: Car jacks are packaged securely to prevent damage during transportation and storage. Clear instructions, user manuals, and safety guidelines are provided to assist users in proper jack operation and maintenance.

Warranty and Customer Support: Manufacturers may offer warranties and customer support services to address any issues or concerns that users may encounter with their car jacks. Prompt assistance and replacement parts availability contribute to customer satisfaction and trust in the product.

Efficency

Quality

Customization

How We Achieve Quality production of radiators?

Quality control is a critical aspect of car radiator manufacturing to ensure that radiators meet stringent industry standards and perform effectively in cooling automotive engines.

- Material Inspection

- Brazing Inspection

- Assembly Inspection

Crafting radiators isn’t just about cooling engines; it’s about engineering reliability, precision, and excellence, one fin, one weld, at a time.!

Machine Zone

By implementing rigorous quality control measures throughout the manufacturing process, car radiator manufacturers can produce radiators that meet high-quality standards, ensuring reliable performance and durability in automotive applications.

Key Features

Contact us

IF YOU ARE INTERESTED IN A PROJECT OR JUST NEED SOME QUESTION

- Wyeth Housing Society Road, off riaiwind road near coca cola lahore.

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.